from the intricate earth of plumbing and HVAC devices, the enlargement tank usually operates driving the scenes, diligently running force fluctuations to safeguard the entire infrastructure. when seemingly simple, its position is critical, and its longevity immediately impacts technique efficiency and routine maintenance prices. Have you ever at any time thought of what actually would make an expansion tank endure the examination of your time? further than the First rate tag, the real price lies in its power to conduct reliably, calendar year soon after calendar year. From content collection to design and style factors and correct servicing tactics, we'll uncover the secrets to maximizing the lifestyle within your growth tanks.for a filter tank producer, we recognize the value of higher-high quality components and precision engineering in extending the lifespan of crucial components like growth tanks. regardless of whether you’re an engineer, contractor, or facility manager, this detailed guidebook will present important insights on maximizing process general performance and cutting down very long-term operational charges.

Table of contents:

the muse: Material range and Corrosion Resistance

structure Matters: Structural Integrity and Internal elements

The Art of producing: Precision and Quality Command

Environmental things: being familiar with the working circumstances

the significance of Maintenance: Proactive measures for Longevity

criteria and Certification: guaranteeing Compliance and good quality

the inspiration: substance assortment and Corrosion Resistance

The products Employed in the construction of an growth tank are the initial line of protection from untimely failure. the choice course of action is not pretty much Expense; It really is about matching the material to the particular functioning surroundings and also the fluid it can have. Let's check out the essential components:

Tank Body content:

stainless-steel Grades: The Gold common: chrome steel, particularly grades like 304, 316, and duplex chrome steel, is commonly the popular choice for expansion tanks on account of its inherent corrosion resistance. Just about every quality features varying levels of security from specific corrosive brokers. For example, 316 stainless steel is made up of molybdenum, which enhances its resistance to chlorides, rendering it ideal for coastal environments or systems employing dealt with h2o. Understanding the particular water chemistry with your method is vital for choosing the right stainless steel grade.

Carbon Steel with protecting Coatings: a price-successful substitute: Carbon metal is usually a feasible possibility if paired with a strong protective coating. The usefulness of the technique hinges on the quality and software of the coating. Epoxy resins and polyurethane coatings are generally employed, but their very long-term overall performance relies on elements like coating thickness, adhesion towards the steel area, and resistance to abrasion and chemical degradation. Regular inspection and servicing of your coating are essential to protect against corrosion from getting keep.

Lined Tanks: An Added Layer of security: For hugely corrosive fluids or Intense functioning circumstances, enlargement tanks with inside linings offer an extra layer of safety. supplies like rubber, PTFE (Teflon), or specialized polymers can make a barrier among the fluid as well as tank's metallic construction, protecting against corrosion and increasing the tank's lifespan. the selection of lining substance must be cautiously matched to the particular fluid being dealt with.

The Integrity of Welds:

Weld Quality: a sequence is simply as solid as Its Weakest Link: The quality of the welds is paramount. Weak or poorly executed welds could become points of failure, bringing about leaks as well as catastrophic rupture. Factors like welding strategy, filler substance variety, and the skill of the welder all lead to weld integrity.

Non-harmful tests (NDT): guaranteeing concealed Flaws are Detected: NDT techniques, such as radiographic tests (X-rays), ultrasonic screening, and magnetic particle testing, are essential for detecting concealed flaws in welds. These tests can reveal cracks, porosity, and various imperfections that may compromise the tank's structural integrity. utilizing a demanding NDT program can be a crucial financial commitment in prolonged-phrase reliability.

Sealing and Fastening:

Seal supplies: stopping Leaks and sustaining strain: the choice of seal resources, for instance O-rings and gaskets, is crucial for blocking leaks. The seal content needs to be compatible Together with the fluid being managed and capable of withstanding the functioning temperature and tension. normal alternative of seals, as Portion of a preventative servicing program, is important for sustaining process integrity.

Fasteners and Connections: protecting against Corrosion-Induced Failure: The products useful for fasteners, like bolts and screws, must even be corrosion-resistant. chrome steel fasteners will often be most popular, specifically in out of doors or humid environments. Proper torqueing of fasteners is usually very important to make certain a safe relationship and stop loosening with time.

structure Matters: Structural Integrity and Internal factors

Beyond substance variety, the look in the enlargement tank plays a vital purpose in its lifespan and durability. A effectively-intended tank minimizes tension, stops corrosion, and ensures the responsible functionality of inner components.

Structural style: reducing Stress and tiredness:

Stress focus: Identifying and Mitigating Weak Points: Sharp corners, abrupt improvements in geometry, and badly intended supports can develop parts of large tension concentration. These parts are at risk of exhaustion failure, In particular less than cyclical pressure loading. Finite element Investigation (FEA) may be used to identify and mitigate worry concentrations in the course of the design and style stage.

Thickness Calculations: making certain satisfactory Strength: The thickness of the tank partitions and conclude caps has to be very carefully calculated to resist the most operating strain with the satisfactory basic safety margin. These calculations will have to keep in mind the material's tensile toughness, generate energy, and corrosion allowance.

help Structures: delivering balance and Load Distribution: The support composition need to be strong adequate to assistance the weight from the tank and its contents, together with any external masses, for example wind or seismic forces. The assistance structure must also lessen pressure to the tank partitions.

inside Design: Optimizing movement and Preventing Corrosion:

stream Baffles: protecting against Stagnation and Sediment Create-Up: in a few applications, flow baffles are utilized to direct the circulation of fluid throughout the tank, protecting against stagnation and also the buildup of sediment. This is especially essential in programs wherever the fluid is made up of particulate subject.

Diaphragms and Bladders: The Heart of your Tank's Function: enlargement tanks typically incorporate diaphragms or bladders to separate the h2o and air cushions. the fabric and building of those components are crucial for their longevity. They must be proof against the fluid staying handled, together with the cyclical pressure of growth and contraction. normal inspection and replacement of diaphragms and bladders in many cases are essential.

floor remedy: maximizing Corrosion Resistance:

Blasting and Cleaning: Preparing the floor for Protection: area planning, for example sandblasting or shot peening, is essential for making a clear and textured area that promotes the adhesion of protective coatings.

Passivation: improving the Corrosion Resistance of stainless-steel: Passivation can be a chemical treatment that boosts the corrosion resistance of stainless steel by forming a thin, protecting oxide layer over the floor.

The artwork of producing: Precision and Quality Management

The production course of action is wherever the look ideas are introduced to life. Precision, excellent Management, and adherence to business criteria are paramount for ensuring the extensive-term trustworthiness of enlargement tanks.

substance reducing: Precision and precision:

specific reducing: reducing squander and Ensuring in good shape: Accurate content reducing is essential for minimizing waste and guaranteeing the tank components in good shape with each other correctly. Personal computer-controlled cutting machines can achieve high amounts of precision.

Forming approaches: Shaping the Tank with Precision:

chilly Spinning and Hot Spinning: Shaping the Tank with Manage: chilly spinning and very hot spinning are frequent methods for forming the tank's stop caps. These procedures need to be very carefully managed to ensure uniform thickness and stay away from anxiety concentrations.

Welding methods: making powerful and Reliable Joints:

GTAW and SMAW: Joining products with talent: fuel tungsten arc welding (GTAW) and shielded metallic arc welding (SMAW) are common welding procedures Utilized in the production of growth tanks. the selection of welding method is dependent upon the components getting joined and the specified weld quality.

Heat cure: Relieving tension and Enhancing Strength:

publish-Weld Heat treatment method: cutting down Residual Stress: article-weld heat treatment method is commonly used to relieve residual stresses from the weld joints, improving upon the tank's All round energy and resistance to fatigue failure.

Environmental Factors: comprehension the running ailments

The surroundings where an growth tank operates can appreciably effect its lifespan. being familiar with these components and taking correct precautions is essential for maximizing longevity.

Temperature Extremes: Impact on components and Seals:

superior Temperature Degradation: deciding upon elements for Heat Resistance: higher temperatures can accelerate corrosion and degrade the Qualities of products, notably seals and diaphragms. choosing components that happen to be rated for that running temperature is important.

reduced Temperature Embrittlement: stopping Cracking in Cold Climates: small temperatures can result in some components to become brittle, growing the chance of cracking. This is particularly essential in cold climates.

force Fluctuations: Fatigue and tension on elements:

Cyclical Loading: coming up with for exhaustion Resistance: Cyclical pressure fluctuations can result in fatigue failure, specifically in regions of higher pressure concentration. coming up with the tank to withstand the expected stress cycles is vital.

Fluid Composition: Compatibility and Corrosion Resistance:

Corrosive Fluids: picking out Corrosion-Resistant supplies: The composition in the fluid becoming managed can have a major influence on the tank's lifespan. Corrosive fluids can attack the tank components, bringing about leaks or failure. picking products which might be appropriate Together with the fluid is vital.

exterior natural environment: safety from The weather:

Outdoor security: protecting against UV Degradation and Corrosion: out of doors publicity can accelerate corrosion and degrade the Attributes of products, especially plastics and coatings. shielding the tank from The weather that has a weatherproof enclosure is recommended.

The Importance of routine maintenance: Proactive methods for Longevity

common routine maintenance is essential for ensuring the extended-phrase trustworthiness of enlargement tanks. Proactive measures can establish opportunity complications early and forestall high priced failures.

frequent Inspections: pinpointing Potential troubles Early:

Visible Inspection: Checking for Corrosion and hurt: common visual inspections can recognize signs of corrosion, leaks, and physical destruction.

tension Testing: Verifying Tank Integrity: Periodic tension tests can confirm the tank's integrity and detect any leaks.

cleansing and Flushing: getting rid of Sediment and particles:

Sediment Removal: Preventing Corrosion and Clogging: Sediment and debris can accumulate during the tank, bringing about corrosion and clogging. Regular cleansing and flushing can stop these challenges.

changing Worn elements: protecting against Failure:

Seal and Diaphragm Replacement: retaining technique Integrity: Seals and diaphragms are subject matter to dress in and tear and may get replaced periodically as Section of a preventative servicing method.

External Coating servicing: Protecting from Corrosion:

Coating Inspection and maintenance: protecting against Corrosion unfold: typical inspection and mend with the external coating can avert corrosion from spreading and compromising the tank's structural integrity.

expectations and Certification: guaranteeing Compliance and excellent

Adhering to business requirements and obtaining certifications are critical for guaranteeing the quality and protection of growth tanks.

style and production specifications: Compliance with field Norms:

ASME and PED: Conference Global expectations: Compliance with sector requirements, including ASME (American Culture of Mechanical Engineers) and PED (force gear Directive), makes certain that the tank is developed and made to satisfy rigorous safety and overall performance prerequisites.

3rd-social gathering Certifications: Verifying excellent and basic safety:

CE and UL: impartial Verification of Performance: Third-occasion certifications, like CE (Conformité Européenne) and UL (Underwriters Laboratories), supply unbiased verification of your tank's more info good quality and protection.

The lifespan and longevity of enlargement tanks are multifaceted, according to a combination of materials selections, design things to consider, production good quality, environmental variables, and diligent upkeep. By knowledge these critical factors and implementing ideal methods, engineers, contractors, and facility managers can considerably increase the life of their expansion tanks, lessen operational prices, and make sure the dependable effectiveness in their methods. for the people seeking dependable and sturdy enlargement tanks created to exacting expectations, consider Discovering alternatives from reliable makers like IWM, recognized for their determination to excellent and innovation in tension vessel technological know-how. Their filter tank and filter tank producer qualifications ensures a amount of expertise you are able to belief.

Mr. T Then & Now!

Mr. T Then & Now! Scott Baio Then & Now!

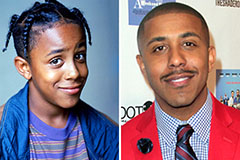

Scott Baio Then & Now! Marques Houston Then & Now!

Marques Houston Then & Now! Mason Reese Then & Now!

Mason Reese Then & Now! Monica Lewinsky Then & Now!

Monica Lewinsky Then & Now!